What are butterfly valves for sale and how to choose one?

In the world of fluid control, butterfly valves play a critical role. They are essential for regulating flow in various systems. John Smith, a leading expert in valve technology, once stated, "Choosing the right butterfly valve can make or break your system." This highlights the importance of understanding your options before making a purchase.

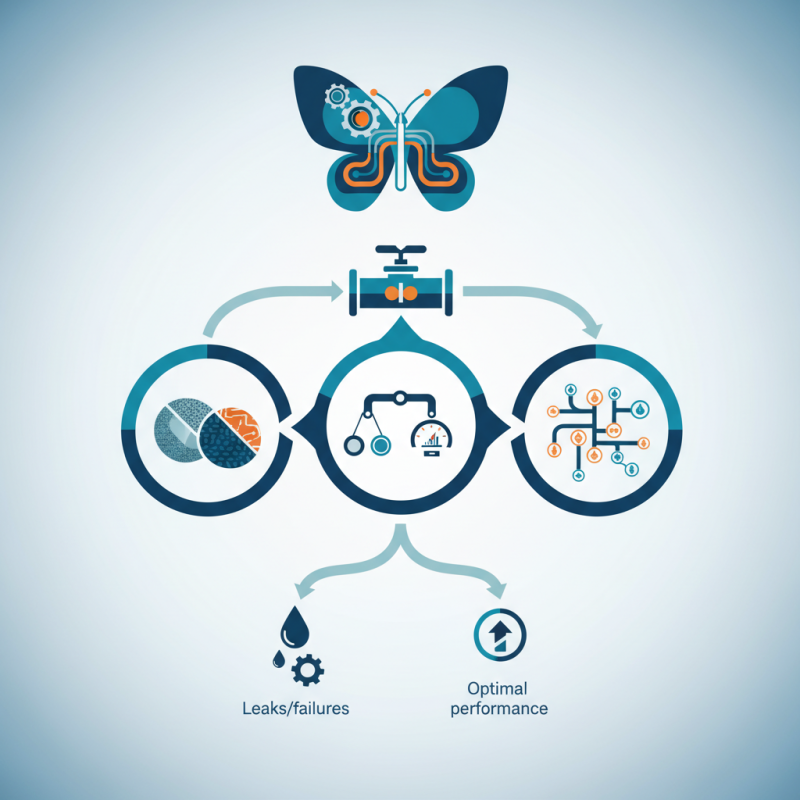

When looking for butterfly valves for sale, it’s vital to consider several factors. Material, size, and pressure ratings are key details to examine. Depending on the application, one type may outperform another. Even minor differences can drastically alter performance. This is an area where many buyers often overlook critical aspects.

Buyers must also reflect on their specific needs. The right valve should match the demands of the environment it operates in. A wrong choice can lead to leaks or system failures. Understanding these variables is not always straightforward, but it is crucial for ensuring optimal performance.

Types of Butterfly Valves Available for Sale

When considering types of butterfly valves available for sale, it’s essential to understand their specific applications. These valves are popular for their ease of use and efficiency. There are various materials available: metal, plastic, and rubber. Each type has unique advantages and disadvantages. For instance, metal valves are durable, while plastic ones offer corrosion resistance.

Another critical aspect is the design. There are different styles, such as lug type and wafer type. The lug type is easier to install in piping systems without an adjoining flange. Wafer type, however, is lightweight and less expensive. It's important to pick the right one for your needs. This choice can depend on several factors, including fluid type and operating pressure.

You may also want to think about size. Butterfly valves come in various diameters. However, choosing the correct size can be tricky. Too small may lead to inefficiency, while too large can be a waste of resources. Lastly, consider how easy it is to maintain. Some valves require regular checks more than others. Researching these factors will guide you towards the best choice.

Key Features to Consider When Choosing a Butterfly Valve

When selecting a butterfly valve, several key features must be considered. The type of piping system is crucial. Different systems require specific designs. Also, the material matters. Common materials include cast iron, stainless steel, and plastic. Each has unique benefits suitable for various applications.

Size plays a vital role too. A valve that is too small may restrict flow. Conversely, a valve that is too large can create inefficiencies. Make sure to measure your piping accurately.

Tips: Always check the pressure rating. Ensure it matches your system's demands. Additionally, consider the operating method. Manual or automated valves have different installation needs. Remember, a poorly chosen valve can lead to issues down the line. Take the time to research thoroughly. Don't hesitate to seek expert advice if needed. Proper selection can save you future headaches.

Materials Used in Butterfly Valve Construction: A Comparative Guide

When choosing a butterfly valve, material selection is vital. Butterfly valves are constructed from various materials, each with unique benefits. Common materials include PVC, cast iron, and stainless steel. PVC is lightweight and resistant to corrosion, making it ideal for water transport. However, it has limitations in high-temperature applications.

Cast iron is durable and cost-effective, suitable for many industrial uses. Yet, it can be prone to rust if not properly coated.

Stainless steel is the go-to for environments that require high resistance to corrosion and heat. This material provides excellent durability but comes at a premium price.

It’s important to think about the specific application before making a choice. For instance, will the valve deal with chemicals or abrasive materials? Does temperature play a role? These aspects can heavily influence material selection.

Sometimes, users may overlook the potential trade-offs between cost and longevity. Choosing the wrong material could lead to frequent replacements, affecting efficiency.

Understanding Butterfly Valve Sizing and Specifications

Choosing the right butterfly valve involves understanding sizing and specifications. The size of a butterfly valve significantly affects its performance and compatibility with your system. For instance, a well-sized valve can optimize flow control and reduce pressure loss. According to industry reports, improper sizing can lead to an alarming 20% efficiency loss in fluid systems.

The specification of a butterfly valve includes parameters like pressure rating, material, and temperature range. These specifications guide users in making informed decisions. A valve with a high-pressure rating might be suitable for demanding environments, while those made of corrosion-resistant materials ensure longevity in aggressive fluids. Always consider the application’s requirements before purchasing.

Tips: Always measure the diameter of the pipe accurately. Cross-check the pressure ratings with system demands. This prevents costly mistakes. Users may overlook the need for regular maintenance. Even the best valve can fail if neglected. Regular checks can ensure better longevity and performance, enhancing system reliability without unexpected downtime.

Tips for Finding Reliable Suppliers of Butterfly Valves

When searching for reliable suppliers of butterfly valves, it’s crucial to do your homework. Start by assessing their experience. A supplier with years in the industry likely understands the nuances of different applications. Check their feedback from past customers, as this can reveal their reliability.

Consider the range of products they offer. A good supplier should have a variety of butterfly valves, including different sizes and materials. This variety will give you choices that fit your specific needs. Compare prices, but be mindful that the cheapest option isn't always the best. Quality matters.

Here are some tips: always ask for certifications. This shows that the supplier follows industry standards. Request samples before bulk buying. This allows you to evaluate the quality personally. Building a good relationship can also help. A trustworthy supplier will support you even after the sale. Effective communication is key. If they are slow to respond, it may signal future issues.

What are butterfly valves for sale and how to choose one? - Tips for Finding Reliable Suppliers of Butterfly Valves

| Valve Size (inches) | Material | Pressure Rating (PSI) | Operating Temperature (°F) | Applications |

|---|---|---|---|---|

| 2 | Cast Iron | 150 | -20 to 200 | Water, Oil |

| 4 | Stainless Steel | 300 | -20 to 400 | Chemical Processing |

| 6 | PVC | 150 | -20 to 140 | Irrigation, HVAC |

| 8 | Ductile Iron | 250 | -20 to 300 | Waste Water Treatment |

| 10 | Aluminum | 150 | -20 to 250 | Air, Gas |